Introduction to Automotive Grade Electronic Components

As a car enthusiast, I'm always fascinated by the technology and innovations that are constantly being introduced into the automotive industry. One such development that has caught my attention recently is the use of automotive grade electronic components. These components are specifically designed to meet the rigorous demands of the automotive environment, ensuring the safety and reliability of the vehicles we drive. In this article, we will explore what automotive grade electronic components are, their significance, and how they differ from other electronic components.

Defining Automotive Grade Electronic Components

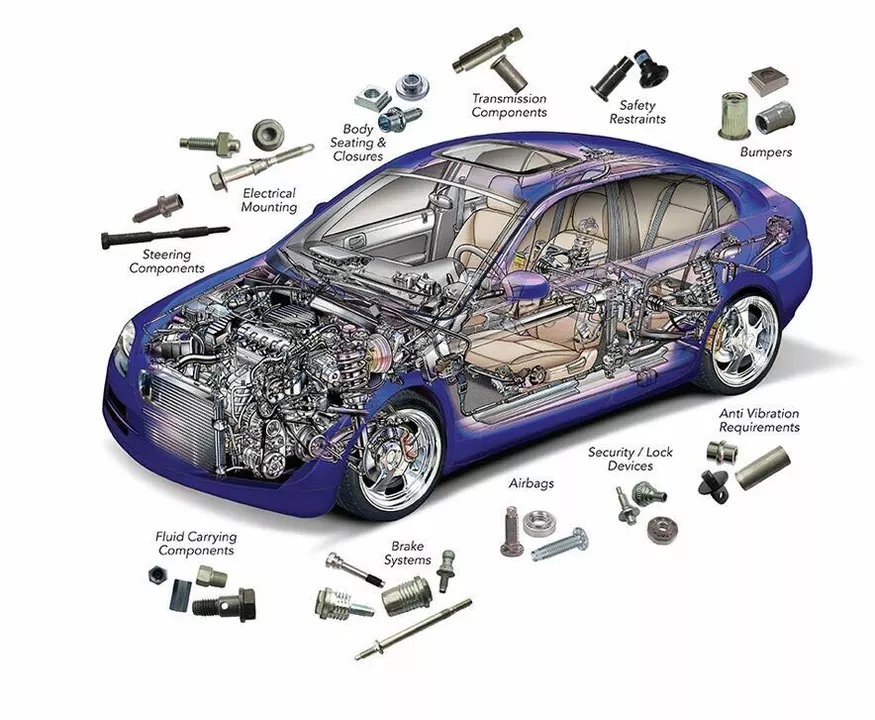

Automotive grade electronic components are parts and devices designed and manufactured to withstand the harsh conditions and requirements of automotive applications. These components are subjected to rigorous testing and quality control processes to ensure their reliability, performance, and durability in the challenging environment of a vehicle. This can include temperature extremes, vibration, humidity, and electromagnetic interference (EMI).

These components are used in a wide range of automotive systems, such as engine control units (ECUs), infotainment systems, safety systems like airbags, and advanced driver assistance systems (ADAS). The use of automotive grade components is essential to ensure the proper functioning of these systems, as well as the overall safety and performance of the vehicle.

Importance of Automotive Grade Electronic Components

The importance of using automotive grade electronic components cannot be overstated. As vehicles become more advanced and incorporate more electronic systems, the need for reliable and durable components becomes even more critical. These components are responsible for the functionality of essential systems, such as engine management, safety features, and comfort systems. A failure in any of these components can lead to a malfunction in the vehicle, resulting in dangerous situations or even accidents.

Furthermore, the use of automotive grade components contributes to the overall longevity of a vehicle. As these components are designed to withstand harsh conditions, they are less likely to fail prematurely, reducing the need for costly repairs and replacements. This, in turn, leads to increased customer satisfaction and a positive reputation for the vehicle manufacturer.

Comparison with Other Electronic Components

Automotive grade electronic components are often compared to their consumer-grade counterparts, which are used in everyday electronics like smartphones, computers, and home appliances. While both types of components serve a similar purpose, there are some key differences between them that make automotive grade components more suitable for use in vehicles.

Firstly, automotive grade components are designed to withstand a wider range of temperatures, from extreme cold to extreme heat, which is a common characteristic of the automotive environment. Consumer-grade components, on the other hand, are usually designed for more stable and controlled environments, such as indoor use.

Secondly, automotive grade components are built to endure higher levels of vibration, shock, and humidity than consumer-grade components. Vehicles experience constant vibrations from the engine and road surface, which can cause damage to delicate electronic components over time. Automotive grade components are designed to resist this damage, ensuring their longevity and reliability.

Lastly, automotive grade components are subjected to stringent testing and quality control procedures to guarantee their reliability and performance. This includes testing for resistance to EMI, as well as ensuring compliance with industry standards and regulations. Consumer-grade components may not be subjected to the same level of scrutiny, making them less suitable for automotive applications.

Quality Standards and Certifications

When it comes to the production of automotive grade electronic components, there are several quality standards and certifications that manufacturers must adhere to. One of the most widely recognized standards is the Automotive Electronics Council (AEC) Q100 series, which outlines the testing and qualification requirements for integrated circuits used in automotive applications.

Another important standard is the International Automotive Task Force (IATF) 16949 certification, which focuses on quality management systems for the automotive industry. This certification ensures that manufacturers follow best practices in design, production, and testing of automotive components to ensure their reliability and performance.

By adhering to these standards and certifications, manufacturers can ensure that their automotive grade electronic components meet the stringent requirements of the automotive industry, providing vehicle owners with peace of mind when it comes to the safety and reliability of their vehicles.

Future Developments in Automotive Grade Electronic Components

As technology continues to evolve, we can expect to see even more advancements in the field of automotive grade electronic components. With the rise of electric vehicles (EVs) and autonomous driving technologies, the demand for high-quality, reliable components will only continue to grow. Manufacturers are constantly working to develop new materials, design techniques, and testing methods to ensure that their components can meet these increasing demands.

Furthermore, as environmental concerns become more prominent, there is a growing focus on developing eco-friendly automotive grade electronic components. This includes using sustainable materials, reducing waste during manufacturing, and improving energy efficiency. By prioritizing sustainability, manufacturers can not only meet the demands of the automotive industry but also contribute to a greener future for all.

Conclusion

Automotive grade electronic components play a vital role in ensuring the safety, reliability, and performance of the vehicles we drive every day. By understanding the importance of these components and the rigorous standards they must meet, we can appreciate the level of care and expertise that goes into their design and manufacture. As technology continues to advance, we can look forward to even more innovations in this field, further enhancing the capabilities and safety of our vehicles.